Introduction

Die casting is a versatile manufacturing process that can utilize various metals to produce high-quality components with intricate details. The choice of material for die casting significantly impacts the cost, weight, and performance of the final parts. Hordrt, a leader in die casting manufacturing, offers expertise in several die casting materials, each with its unique properties and advantages. This article explores the key materials used in die casting, including aluminum, zinc, and magnesium, and highlights their benefits and applications, particularly in the context of vacuum casting rapid prototyping.

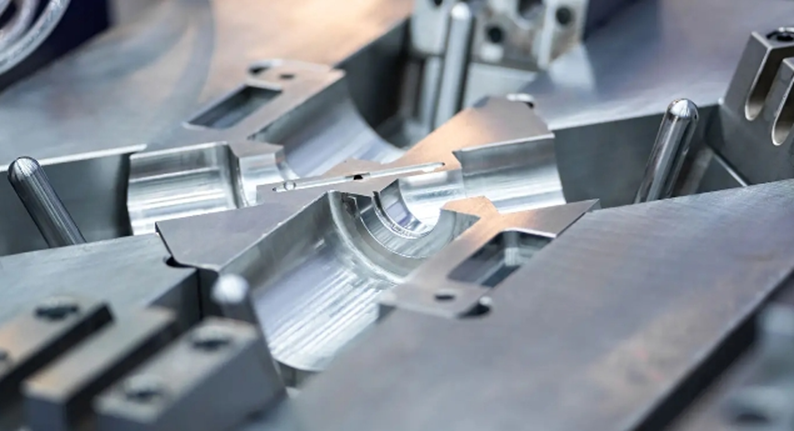

Aluminum Die Casting

Aluminum alloys are the most commonly used materials in die casting due to their favorable properties. Aluminum is prized for its lightweight nature, high-temperature resistance, and excellent corrosion resistance. These attributes make it an ideal choice for producing a wide range of components across various industries. The use of aluminum alloys in die casting ensures that parts are not only durable but also lightweight, which is crucial for applications where reducing weight is essential. Hordrt utilizes aluminum die casting to manufacture high-quality components that meet stringent performance standards, making it a reliable choice for vacuum casting rapid prototyping.

Zinc Die Casting

Zinc is another versatile material widely used in die casting, known for its high-performance characteristics. Zinc’s strength and stiffness allow for the production of parts with thinner walls and highly detailed features while maintaining tight tolerances. This material’s versatility makes it suitable for applications requiring precise and intricate components. Zinc die casting is particularly beneficial for producing parts that need to withstand significant mechanical stress while maintaining a high level of detail. Hordrt leverages zinc die casting to deliver components that excel in both performance and precision, supporting advanced vacuum casting rapid prototyping projects.

Magnesium Die Casting

Magnesium is a preferred material for die casting when dealing with complex castings. Its high tolerance and enhanced corrosion resistance make it suitable for applications where both strength and durability are crucial. Magnesium’s unique properties allow for the creation of intricate designs and complex geometries, making it an excellent choice for demanding applications. The use of magnesium in die casting ensures that parts are not only strong and resistant to corrosion but also capable of withstanding challenging environments. Hordrt incorporates magnesium die casting to produce high-performance components that meet specific industry needs, enhancing their capabilities in vacuum casting rapid prototyping.

Conclusion

Choosing the right material for die casting is essential for achieving optimal performance, cost-efficiency, and durability of components. Hordrt, a prominent name in die casting manufacturing, offers extensive expertise in using aluminum, zinc, and magnesium for die casting applications. Each material provides unique benefits, from the lightweight and corrosion-resistant properties of aluminum to the precision and strength of zinc, and the high tolerance and durability of magnesium. By integrating these materials into their vacuum casting rapid prototyping services, Hordrt ensures that clients receive high-quality, reliable components tailored to their specific requirements.